How to address trust and security when your electronics are 1,200 miles away

Dr. Bill Conley, CTO

October 14, 2021

Trust and security are paramount design factors for any defense system. The safe operation of critical systems in the aerospace and defense market is an obvious expectation. When you look at how we learned to make our systems trusted and secure for safe operation, it was largely through forensic examination after an incident. Still today, we strive to improve our systems through investigations by the National Transportation Safety Board, better known as the NTSB. For terrestrial applications, we can determine why a system failed: Was it hacked? Did it break due to a poor design? Did it suffer a mechanical failure due to fatigue? Was the supply chain compromised? Aircraft can be reassembled after an incident and each component can be examined. Ultimately, the lessons learned are flowed back to the industry base. Perhaps a design change is needed to update the system. Perhaps a new security application must be loaded. Perhaps a board needs to be replaced with better microelectronics due to the inclusion of a counterfeit part. This is a strategy, policy and process that we understand well…for terrestrial applications.

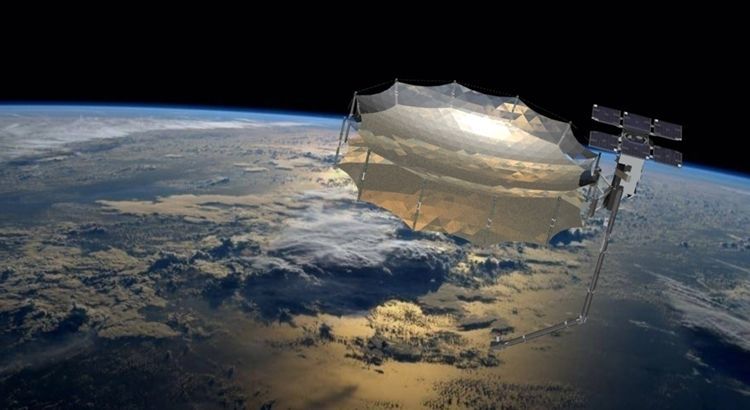

The problem is very different, however, when we consider trust and security of critical space operations at least 1,200 miles above the surface of the Earth. Human spaceflights are increasingly common with more civilians going to space. However, the total number has still not reached 600. Only 24 people have ever traveled beyond Low Earth Orbit (LEO). Publicly available data shows just over 11,000 satellites have been launched with 7,389 currently in space. One could claim that we need more astronauts to go investigate all of our satellites to ensure they are working in an appropriate safe, secure and trusted manner. Unfortunately, this isn’t viable and it doesn’t scale as proliferated Low Earth Orbit (pLEO) becomes increasingly common. At the same time, many new space missions are using commercially available microelectronics to improve performance and reduce costs, but these lack strategic oversight of the supply chain components and may present national security with an unknown level of risk. We require a new framework for trust and security for space-based applications.

At Mercury Systems, we have extensive experience with trusted and secure microelectronics, ensuring the supply chain is at the core of everything we do. Delivering components, modules and subsystems to critical national security applications while meeting the harshest environmental conditions is foundational to our business. Decades of investment in secure processing provides best-in-class confidence that only the right signals are being processed and desired data is flowing out of a system. This is critical for radar, electronic warfare or mission computing modules for an aircraft, ship, or ground vehicle. These same principles are directly applicable to space-based systems. When your mission can’t fail during a crisis, you have to “design in” the trust and security to ensure safe operation when it counts.

Operations at high altitudes, with continuous exposure to corrosive salt water or experiencing extreme temperature swings are all environmental conditions that we’ve designed electronics to operate in for over four decades. Today, we’re increasingly designing systems to operate through, or to survive, the effects of radiation – both natural and man-made. We’ve brought our legacy of a trusted supply chain, our deep understanding of security, and added the harsh environment of radiation to our factors to consider. Whether it’s a space drive, a critical microwave component or a processing module, we understand how to develop, test and deliver to meet the requirements.

Get some quarters, we’re going to the arcade.

Get some quarters, we’re going to the arcade. Microelectronics Powering the New Space Economy

Microelectronics Powering the New Space Economy