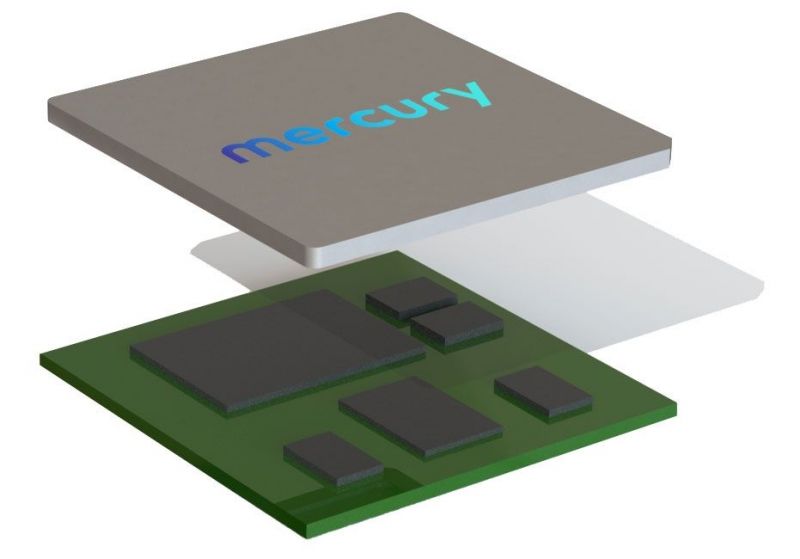

Custom Device Packaging & Integration

Trusted 2.5D system-in-package and multi-chip module solutions

Trusted 2.5D system-in-package and multi-chip module solutions

INTEGRATED MANUFACTURING

From custom microelectronics to complex systems, our integrated manufacturing capability leverages common processes and innovative technologies documented and certified—to minimize your risk.

To deliver the latest commercial technology purpose-built for mission-critical aerospace and defense applications, we start at chip scale with our high-density system-in-package technology, designed and manufactured in trusted and secure DMEA-accredited facilities.

From custom microelectronics to complex systems, our integrated manufacturing capability leverages common processes and innovative technologies, documented and certified, to minimize your risk.

Direct RF multi-chip module (MCM) with AMD Versal FPGA, high-speed sensor processing, and wideband data converters

SOSA-aligned microwave transceiver

Multiple bandwidth microwave downconverter

Learn about critical technology for next-gen army vehicle autonomous driving, navigation and...

Learn about Mercury's data recorder solutions for sophisticated technologies to manage and analyze...

In this interview, Vincent Pribble, Principal Product Manager at Mercury Systems, discusses current...

DRFM-based radar environment simulators and radar target generators are efficient, cost-effective...